Our Associates

Solutions & Services

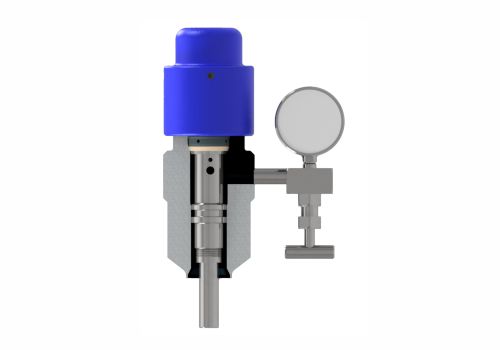

- Corrosion Monitoring

- Pipeline Pigging & ILI

- Composite Wrapping

- Green Energy Solutions

Products & Innovations

Contact Us

D-183/1, MIDC Shirvane,

TTC Industrial Area, Nerul,

Navi Mumbai-400706, (India)

Quick Enquiry

Copyright © 2025 Pyramid Technical Services. All Rights Reserved.